We receive requests from automobile manufacturers during the rough design stage.

Based on those requests, we suggest designs, internal mechanisms, wiring, and parts to use that will fulfill the customer’s needs.

Fusing design sense and functionality in the completion process, we make side-view mirrors that satisfy customers, while coming up with various ideas and having repeated discussions.

Completing Products by Fully Utilizing Knowledge and Technology

Design

Concept

Based on the rough designs for the side-view mirrors presented by the automobile manufacturer, we solidify the product concept through discussions from various perspectives, including comparisons with other company’s products, patent-related issues, and costs. In line with the product concept, we suggest a design concept that pursues productivity and quality.

Design

Development

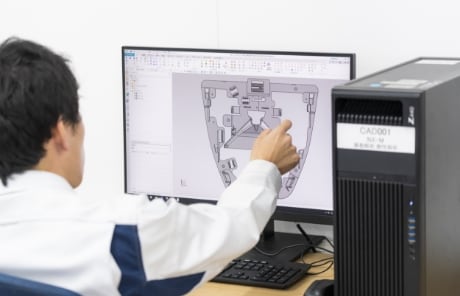

After deciding on the design concept, we apply a proper design that fulfills functionality and reflects customer needs.

Detailed

Design

Next, we design the internal unit for the design that was decided on. It differs depending on the manufacturer and car model, but usually there are around 60 parts used in a side-view mirror. To create a lightweight and compact product that meets the needs of our customers, we reduce the number of components used as much as possible and aim for high-quality manufacturing.

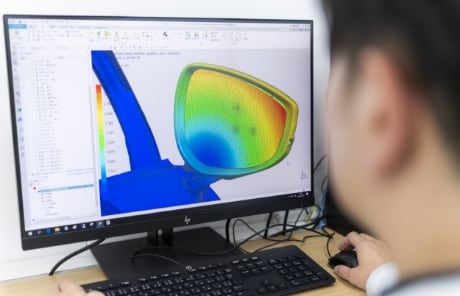

Design

Verification

After deciding on the detailed design, we conduct design verification by bringing together our vast knowledge, including electrical engineering, electronics, mechanical engineering, and material mechanics. When conducting design verification, we fully utilize the latest computer technology, and conduct aerodynamic analysis and vibrational analysis using rapid models (prototypes) created with 3D-CAD. In addition, we conduct CAE analyses including flow analysis and rigidity analysis, verifying productivity, appearance quality, and rigidity.

Wind Tunnel

We have equipment for wind tunnel experiments installed in our company and conduct aerodynamic analysis by actually blowing wind on our prototypes.

Preparing for

Production

We create a prototype and confirm if it matches with customer needs and productivity. If the prototype clears this part of the process, we set manufacturing control conditions for mass production, and then begin production.

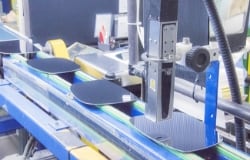

Mass

Production

After the prototype is sent to the production line, we confirm if it is being mass produced in accordance with the set manufacturing control conditions. If we find even the slightest problem, we quickly handle the issue and solve it.

-

Molding

-

Painting

-

Making the Mirror

-

Assembly

-

Inspection

-

Shipping

Education Hall

For our employees who have just recently arrived at our factories, we give complete training on basic knowledge and technology, including our manufacturing processes and safety management. This is to ensure a smooth start for them as they enter their actual workplaces.